Login

Our Airgineers Can Help You Select The Right Product!

Contact Us

Reliable Compressed Air Quality for Electrical & Electronics Operations – Prevent Downtime, Ensure Efficiency

Uncontrolled humidity and oil aerosols in compressed air lead to corrosion, faulty instrument air, and product defects. Delair’s engineered & highly efficient refrigeration and adsorption Air dryers—paired with precision filtration—deliver clean and dry air that protects sensitive assemblies, instruments, and test rigs.

Why Dry, Clean Air Matters

Electrical and electronics manufacturing depends on compressed air for pneumatic valves operations, pick-and-place systems, PCB cleaning, blow-off, coating, and testing. However, ambient humidity and compressor carryover introduce moisture, oil aerosols, and particles that silently degrade quality. Effects range from oxidation on contacts and busbars to lens fogging, solderability issues, insulation tracking, and inconsistent machine behavior. The result is higher reject rates, rework, and unplanned downtime.

Challenges in the Electrical & Electronics Industry

Untreated compressed air is a hidden cost center in electrical and electronics (E&E) operations. Moisture condenses in lines and tools, causing corrosion of valves, cylinders, fixtures, and connectors. Oil aerosols foul instruments and contaminate surfaces prior to soldering, conformal coating, or painting. Particulate matter accelerates tool wear and compromises metrology, while dew-point drift reduces mean time between failures (MTBF) for actuators and relays.

Common problems caused by poor air quality:

- Corrosion of busbars, terminals, connector pins, and pneumatic components

- Condensation inside panels leads to insulation tracking/flashover risk

- PCB defects: poor adhesion, delamination risk, flux entrapment, coating pinholes

- Lens/mirror fogging in optical inspection and exposure equipment

- Sticking/erratic Pneumatic Valves Operations in handling and assembly lines

- Higher reject rates and rework; line slowdowns and unplanned stoppages

- Clogged nozzles and premature filter/desiccant failures increasing maintenance cost

In humid climates and on long outdoor runs, instrumentation air is especially vulnerable: even small dew-point rises can cause water to drop out in low points, creating corrosion, valve sticking, and spurious sensor behavior that inflate OPEX and jeopardize delivery schedules.

Applications That Require Compressed Air Dryers Alongside Compressors

Wherever a compressor is specified in E&E manufacturing, a dryer should be specified alongside it to prevent liquid water formation and oil carryover. Key applications include:

Instrumentation Air for Control and Automation

Pneumatic logic, I/P converters, positioners, and small actuators require a consistently low pressure dew point. Dryers prevent condensation in tubing, avoid rust, and keep response times stable across shifts and seasons.

Pneumatic Valves Operations in Assembly and Handling

Pick-and-place, conveyors, grippers, and indexing systems rely on clean, dry air to avoid sticking spools, clogged mufflers, and sluggish cylinders that create micro-stoppages and mis-picks.

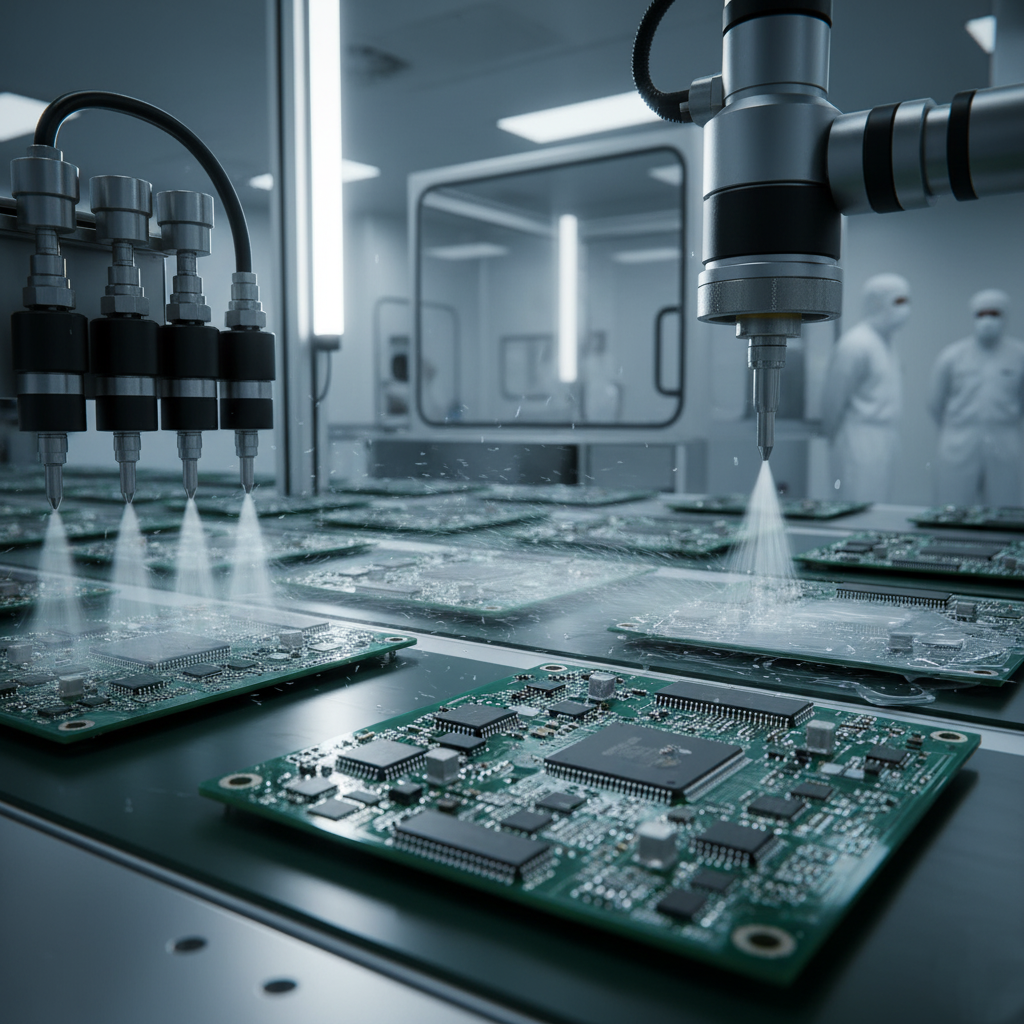

PCB Assembly: Blow-off, Cleaning and Conformal Coating

Moisture and oil aerosols can cause solderability issues, ionic contamination, coating fisheyes, and pinholes. Dryers ensure consistent surface prep and coating outcomes.

Panel and Switchgear Manufacturing

Dry air protects contact surfaces, prevents insulation tracking, and keeps tools/gauges reliable during enclosure fabrication, painting/powder coating, and final testing.

Cable and Conductor Plants

Extrusion support air, post-wash drying, and leak/pressure tests demand stable dew point to avoid moisture entrapment and test variability.

How Delair Solves It

Delair designs end-to-end compressed air treatment trains tailored to electrical and electronics applications—stabilizing dew point, removing water and oil aerosols, and protecting instruments and processes.

Refrigeration Dryers (FDI Series)

- Based on the principle of cooling air close to the freezing point, refrigeration dryers remove moisture efficiently.

- Pressure Dew Point (PDP): +3°C to +4°C.

- Eco-friendly refrigerants with energy-saving designs for tropical conditions.

- Available in 45 standard models with flow rates from 18 m³/hr to 6,000 m³/hr.

- Compact design with proprietary heat exchangers and optional explosion-proof controls.

- (Internal link: Delair Refrigeration Dryers page)

Adsorption (Desiccant) Dryers (DD/DC Series)

- For critical applications requiring ultra-dry air, Delair’s desiccant dryers provide Atmospheric dew points as low as (–) 40°C to (–) 70°C.

- Special graded DelSorb™ desiccant ensures long life and optimal adsorption.

- Electronic controls and solid-state timers for reliable, automatic operation.

- Flow range: 6 m³/hr to 2,030 m³/hr (3.5 CFM to 1200 CFM).

- Engineered specifically for ultra-dry air in critical process controls.

- (Internal link: Delair Adsorption Dryers page)

Filtration & Condensate Management

- Multi-stage filters eliminate oil aerosols, vapors, and solid particulates.

- Condensate management units with oil-water separators ensure compliance with environmental standards.

- Zero-loss drains for efficient, sustainable operations.

- (Internal link: Delair Filters & Condensate Management solutions)

By integrating dryers, filters, and separators, Delair delivers a complete downstream air treatment system—ensuring equipment protection, operational continuity, and industry compliance.

Benefits of Choosing Delair

Choosing Delair means choosing reliability and expertise built over decades in compressed air treatment.

Key Benefits:

- Consistent supply of clean, dry, compressed air.

- Stable Instrumentation Air improves actuator/valve life and MTBF.

- Compliance with ISO 8573-1 standard.

- Reduced maintenance costs and extended equipment lifespan.

Call to Action

Protect your operations with reliable compressed air treatment solutions from Delair. Our experts are ready to guide you in selecting the right system for your application.

📩 Contact us today at:

Our Airgineers Can Help You Select The Right Product!

Contact Us